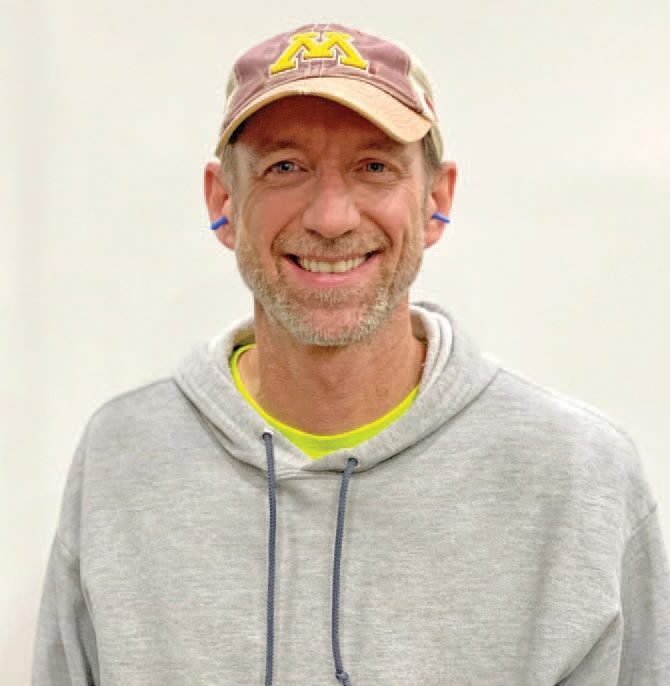

Chad Pederson, machinist and member of the 25-year club, began at Akkerman on September 30, 1996. Chad was nominated for his ambition and willingness to mentor new machinists.

Nominated because:

“For coming through on programming and running a customer job shop order.”

“For training and mentoring newer machinists.”

“Willing to come in during off-hours to work on a machining center when it was down.”

“Helps employees on both shifts on pilot tube machine operation.”

Admirable Qualities:

- Consistent

- Loyal

- Nice Person